DAYTON Bench Grinders

Dayton bench grinders are suitable for shaping, grinding and sharpening metal tools, tips, sheets & pieces in refurbishing, manufacturing & maintenance applications.

Combination Belt and Bench Grinders

Bench Grinders

Bench grinders are suitable for shaping, grinding and sharpening metal tools, tips, sheets and pieces in refurbishing, manufacturing and maintenance applications. These grinders generally feature an abrasive grinding wheel or belt that runs at high speeds to form, shape or smoothen a workpiece.

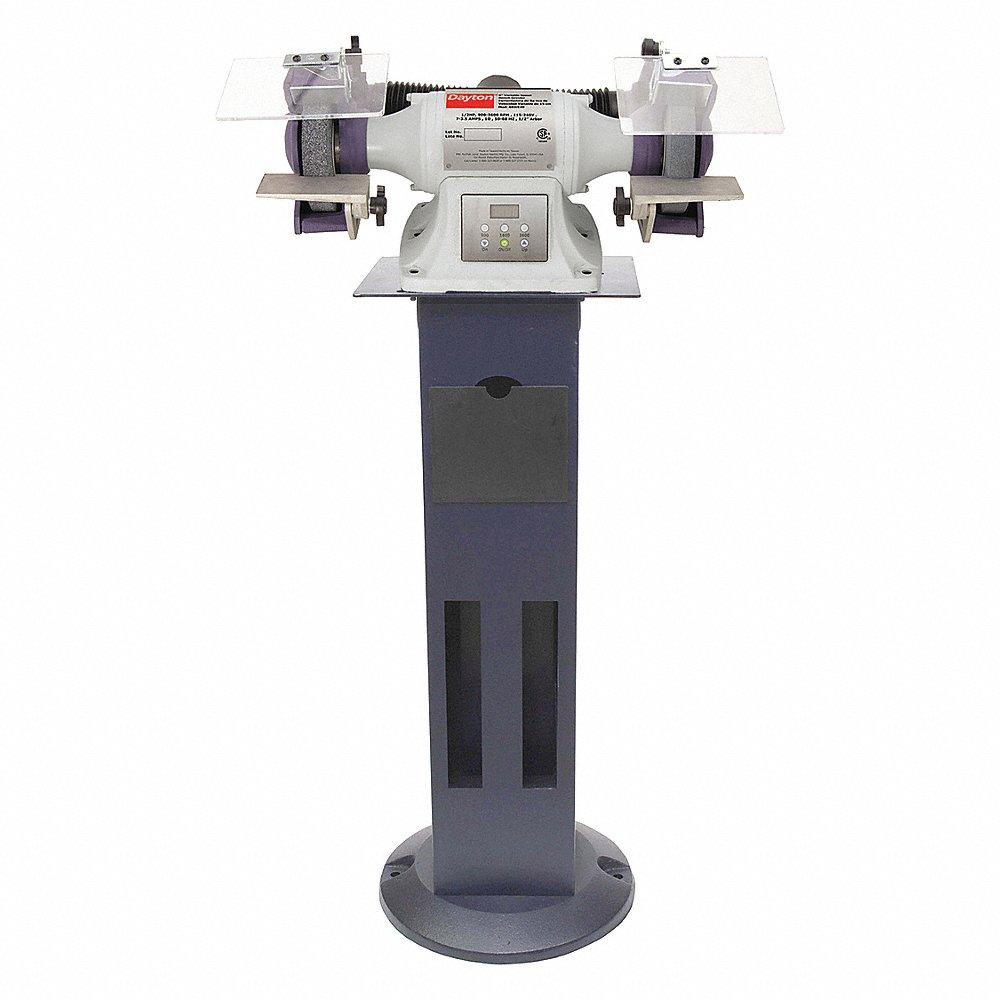

Dayton bench grinders use an electric motor for deburring, grinding, cleaning, sharpening and chamfering jobs of metal blocks or pieces. They have dynamically balanced armature assembly with sealed bearings for ensuring smooth running, noiseless operation and minimum vibrations. These Dayton grinders are equipped with grinding wheels or a wire brush having a large wheel to wheel clearance and OSHA compliant wheel guards for easy grinding of longer items and increased user safety. Dayton grinders have two separate wheels having different grit sizes for catering to diverse types of grinding & abrasive applications. They have heavy duty enclosed motors with 1/3 to 3 hp power outputs for rotating the wheels continuously at maximum speeds ranging from 1725 to 3450 rpm. The motors can also be fitted with a variable speed, controlled by a mechanical dial to change the wheel rotation speed. These Dayton bench grinders can be adjusted easily by the users to allow efficient tilt & angle grinding applications. They also have safety features like adjustable safety eye shields & easily positioned spark guards with hurricane bolts for protecting users & surrounding machinery from injuries or fire hazards. These Dayton grinders have aluminium & steel or cast iron construction for strength & corrosion resistance. Selected Dayton grinders have a pedestal floor stand with a quench tray for operating the unit while standing & reducing frequent bending related injuries to users. Some models of Dayton grinders come with a patented single dust port collection system for cleaning away grounded materials from the industrial work environments.

Choose from a wide range of these Dayton grinders, available in wheel diameters of 6, 8, 10 and 12 inches.

Bench grinders are suitable for shaping, grinding and sharpening metal tools, tips, sheets and pieces in refurbishing, manufacturing and maintenance applications. These grinders generally feature an abrasive grinding wheel or belt that runs at high speeds to form, shape or smoothen a workpiece.

Dayton bench grinders use an electric motor for deburring, grinding, cleaning, sharpening and chamfering jobs of metal blocks or pieces. They have dynamically balanced armature assembly with sealed bearings for ensuring smooth running, noiseless operation and minimum vibrations. These Dayton grinders are equipped with grinding wheels or a wire brush having a large wheel to wheel clearance and OSHA compliant wheel guards for easy grinding of longer items and increased user safety. Dayton grinders have two separate wheels having different grit sizes for catering to diverse types of grinding & abrasive applications. They have heavy duty enclosed motors with 1/3 to 3 hp power outputs for rotating the wheels continuously at maximum speeds ranging from 1725 to 3450 rpm. The motors can also be fitted with a variable speed, controlled by a mechanical dial to change the wheel rotation speed. These Dayton bench grinders can be adjusted easily by the users to allow efficient tilt & angle grinding applications. They also have safety features like adjustable safety eye shields & easily positioned spark guards with hurricane bolts for protecting users & surrounding machinery from injuries or fire hazards. These Dayton grinders have aluminium & steel or cast iron construction for strength & corrosion resistance. Selected Dayton grinders have a pedestal floor stand with a quench tray for operating the unit while standing & reducing frequent bending related injuries to users. Some models of Dayton grinders come with a patented single dust port collection system for cleaning away grounded materials from the industrial work environments.

Choose from a wide range of these Dayton grinders, available in wheel diameters of 6, 8, 10 and 12 inches.

| Style | Model | Overall Length | Item | Amps | Arbor Size | For Max. Wheel Dia. | Grinding Wheel Grit | Grit | HP | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 467L32 | €1,712.35 | |||||||||

| B | 467L85 | €943.65 | |||||||||

| C | 2LKT1 | €666.57 | |||||||||

| D | 467L64 | €4,881.90 | |||||||||

| E | 467L65 | €1,729.21 | |||||||||

| F | 2LKR8 | €474.99 | |||||||||

| G | 2LKR6 | €363.30 | |||||||||

| H | 48WE50 | €1,307.34 | |||||||||

| I | 467L67 | €3,175.14 | |||||||||

| J | 499F65 | €626.55 | |||||||||

| K | 467L63 | €4,484.69 | |||||||||

| L | 2LKT2 | €1,098.90 | |||||||||

| M | 400H42 | €342.24 | |||||||||

| N | 467L84 | €356.99 | |||||||||

| O | 467L28 | €3,492.32 | |||||||||

| P | 499F64 | €458.62 | |||||||||

| Q | 467L29 | €3,983.95 | |||||||||

| R | 467L66 | €1,895.33 | |||||||||

| S | 467L83 | €361.17 | |||||||||

| T | 467L31 | €1,118.93 | |||||||||

| U | 400H41 | €196.77 | |||||||||

| V | 48WE51 | €2,120.99 | |||||||||

| W | 467L33 | €2,502.03 | |||||||||

| X | 467L82 | €371.91 | |||||||||

| Y | 467L30 | €4,457.53 |

Features

- Dayton bench grinders feature an abrasive grinding wheel or a belt that runs at high speeds to form shapes or smoothen a workpiece.

- They use an electric motor for deburring, grinding, cleaning, sharpening and chamfering metal blocks or pieces and have dynamically balanced armature assembly with sealed bearings for smooth running, noiseless operation & minimum vibrations.

- Most units have two separate wheels with different grit sizes for catering to diverse types of grinding & abrasive applications.

- These units feature heavy-duty, enclosed motors for rotating the wheels continuously at speeds ranging from 1725 to 3450 rpm.

- They can be fitted with a variable speed control (a mechanical dial) to change the wheel rotation speed, allowing efficient tilt & angle grinding.

- These products feature aluminium & steel or cast iron construction for strength & corrosion resistance.

- They have safety features like adjustable safety eye shields & easily positioned spark guards with hurricane bolts for protecting users & surrounding machinery from injuries or fire hazards.

- Selected Dayton grinders (including 38UK64 units) have a pedestal floor stand with a quench tray for operating the unit while standing & reducing frequent bending-related injuries.

Working Mechanism

- Stand on one side of the grinder until the wheel reaches its operating speed.

- Gently bring the workpiece in touch with the grinding wheel.

- Apply gentle pressure initially to allow the wheel to warm up uniformly.

- Use only the amount of pressure necessary to perform the grinding operation.

Standards and Approvals

- OSHA

- CE

- CSA

Frequently Asked Questions

Why do bench grinders have 2 wheels?

- The first wheel is suitable for fine precision and sharpening work, while the other is ideal for rough shaping.

- These wheels can be effortlessly swapped out for different wheel configurations.

What to do in case of grinder failure?

- Check the status of the wiring connections, fuse & capacitor.

- Check & clean dirt or dust accumulated on wheels and shaft, which might cause the motor to heat up.

- Motor bearings should be lubricated regularly for smooth operation.

- Do not wedge any material between the wheel and the guard.

- Check for wear & tear on grinder parts.

- Users might face vibrations & irregular grinding due to improper mounting of the wheels or the unit on the stand.

Which materials are incompatible with a Dayton grinding wheel?

Never grind wooden, plastic or non-metallic materials using a Dayton grinder. These bench grinders are not designed to grind / sand such materials.

We are here to help!

Looking for a part not listed here?

Explore More

- Dust Mops Dusters and Cleaning Pads

- Hammers and Striking Tools

- Tensioners and Tighteners

- Indexable Tools

- Noise Control

- Insulated Tool Sets

- Open End Wrench Sets

- Pallet Tamper Resistant Kits and Tools

- Wire Shelf Posts

- Adhesion Tester Accessories

- KINEDYNE Transport Chain 4700 Lb

- DIXON Floating Flanges

- BALDOR MOTOR Grain Dryer/ Centrifugal Fan Farm Duty Motors, Three Phase, Totally Enclosed Cooled

- ABC HAMMERS Bronze/Copper Sledge Hammers

- EATON FDC Series Complete Molded Case Circuit Breakers, F Frame

- MILLER BY HONEYWELL Winchs

- GROVE GEAR EL Series, BMQ-R Style, 821 Size, Aluminium Worm Gear Reducers

- GROVE GEAR EL Series, B-D Style, EL Series, B-D Style, 821 Size, Aluminium Worm Gear Reducers

- HOSHIZAKI Bases

- JONES STEPHENS Cutters